Jodoo Lean Management Solution

Revolutionize your lean management process with a no-code, full-process digital workspace. Empower your organization with flexible tools, comprehensive scenario templates, and seamless digital execution to drive continuous improvement and full team engagement.

Trusted by businesses worldwide

Lean should be easy — but these problems make it hard

Inefficient Process Tracking and Management

Manual spreadsheets, Excel files, or paper records make it hard to track progress in real-time, causing delays in decision-making and process improvements.

Challenges in Cross-Department Collaboration

Lean improvement projects often require multiple departments to work together, but poor communication and feedback systems result in delays and inefficiencies.

Lack of a Flexible and Customizable Toolset

Lean tools like 5S, suggestion systems, or project management tools are inconsistently applied, leading to significant variations in implementation results.

Difficulty in Quantifying Improvement Results

Measuring the outcomes of lean projects is challenging, making it harder to use data-driven insights for effective decision-making and continuous improvement.

Sustainability of Improvements is Difficult

Lean improvements often weaken over time, as maintaining long-term results requires consistent effort, regular monitoring, and proper resource allocation, which can be challenging.

Low Employee Engagement in Lean Initiatives

Frontline employees are often disengaged due to complex proposal processes, lack of transparency, and insufficient incentives, reducing participation and innovation.

Highlights of our Solution

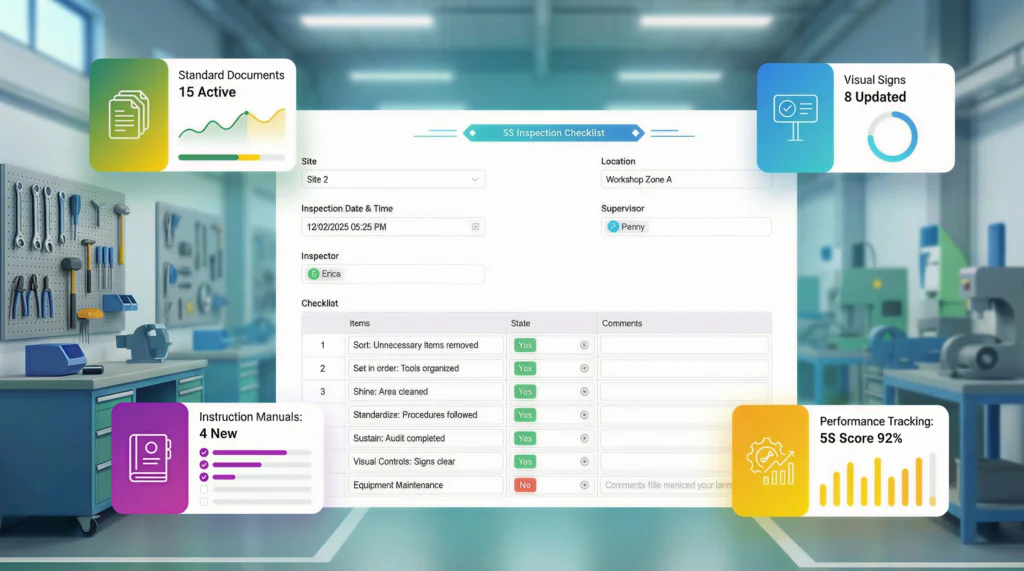

5S and Visual Workplace

- Streamlined Digital 5S Inspection Forms — Simplify data entry and ensure accurate record.

- Visualized Inspection Tasks – Create online corrective workflows for non-conformities and track every action to ensure 100% resolution and accountability.

- Centralized Management of Visual Labels and Documentation – Manage visual labels, instruction documents, and guidelines in one place to drive continuous on-site improvements.

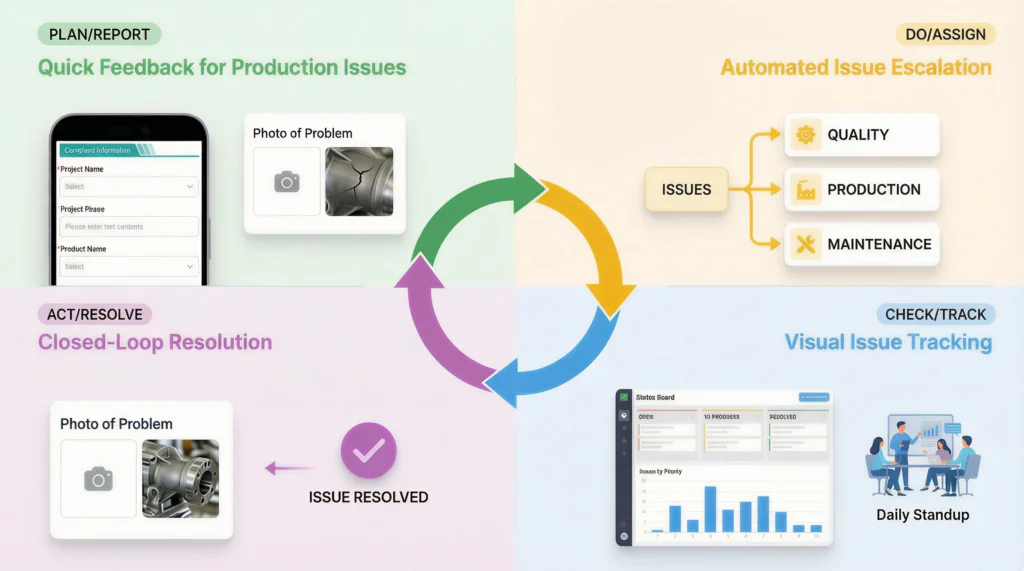

Production Issue Tracking

- Quick Feedback for Production Issues – Enable fast reporting of production issues with support for photo and video capture, simplifying the input process.

- Automated Issue Escalation – Once an issue is reported, it is automatically assigned to relevant departments using tiered response mechanisms to ensure timely information flow and resolution.

- Visual Issue Tracking – Track and review unresolved production issues during daily meetings to ensure 100% closure and accountability.

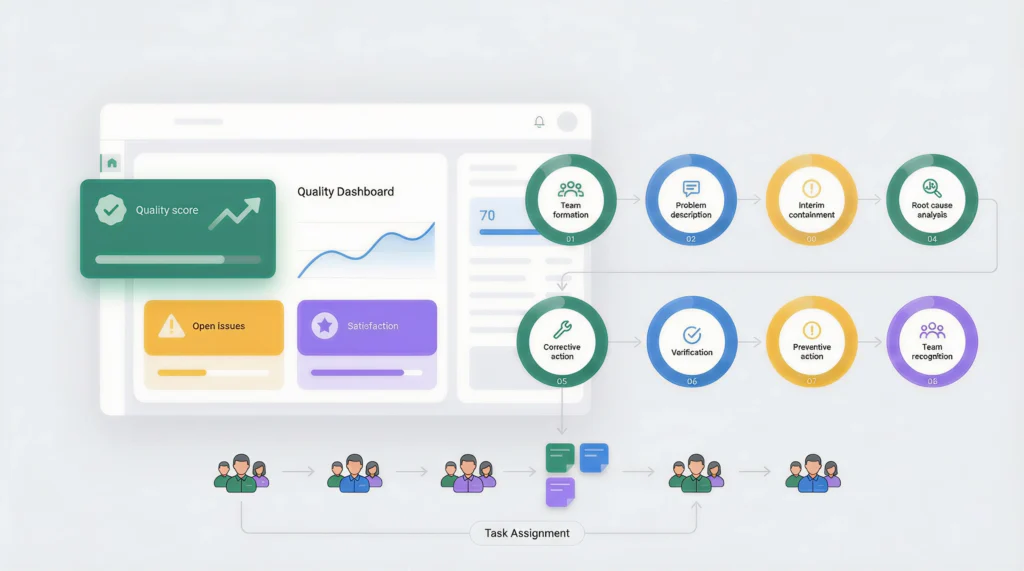

Lean Quality Management

- Rapid Quality Control – Quickly isolate suspicious materials on the shop floor and quarantine defective batches to prevent quality risks.

- Tiered Approval Mechanisms – Support multi-level approval workflows to ensure quality review tasks are executed accurately and efficiently.

- Comprehensive Issue Handling Workflow – Analyze quality issues in detail and verify the implementation of corrective and preventive actions to ensure long-term improvement.

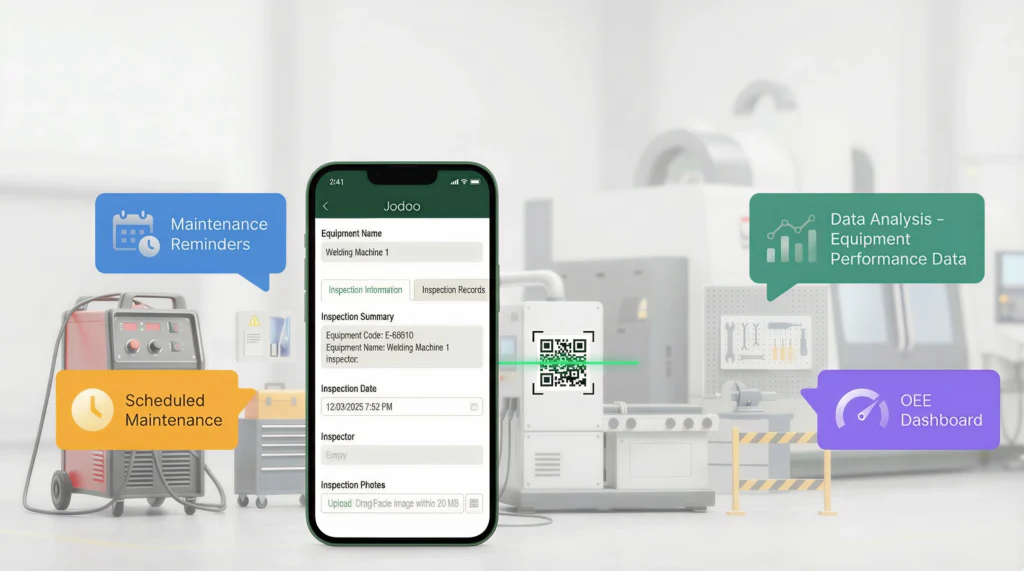

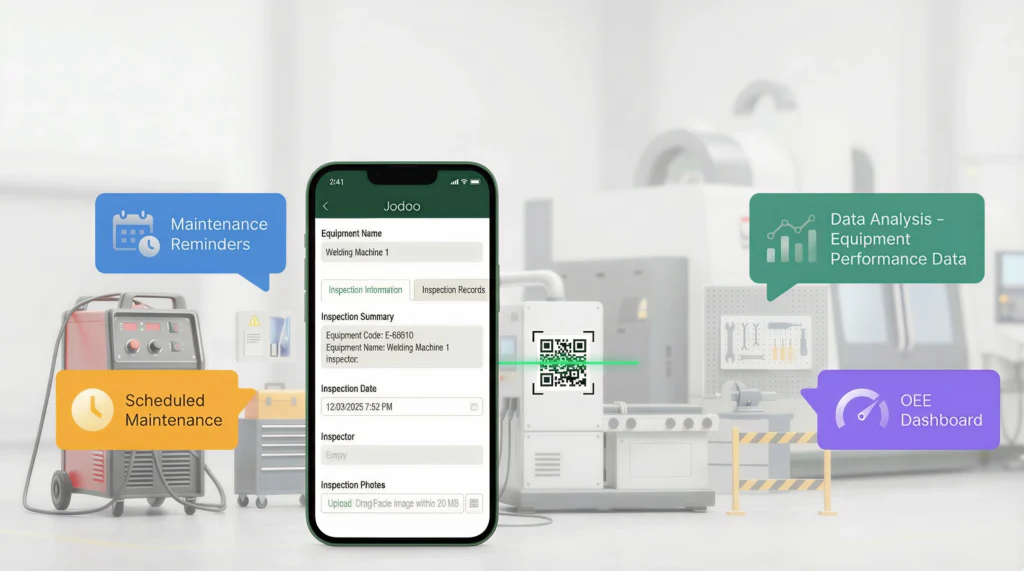

Total Production Maintenance

- Equipment Inspection – Digitize equipment inspection tasks with electronic checklists to ensure thorough monitoring.

- Equipment Maintenance – Set up scheduled maintenance reminders, streamline repair workflows for equipment failures, and manage spare parts inventory effectively.

- Equipment Data Analysis – Utilize OEE (Overall Equipment Effectiveness) dashboards to monitor equipment performance and identify improvement opportunities.

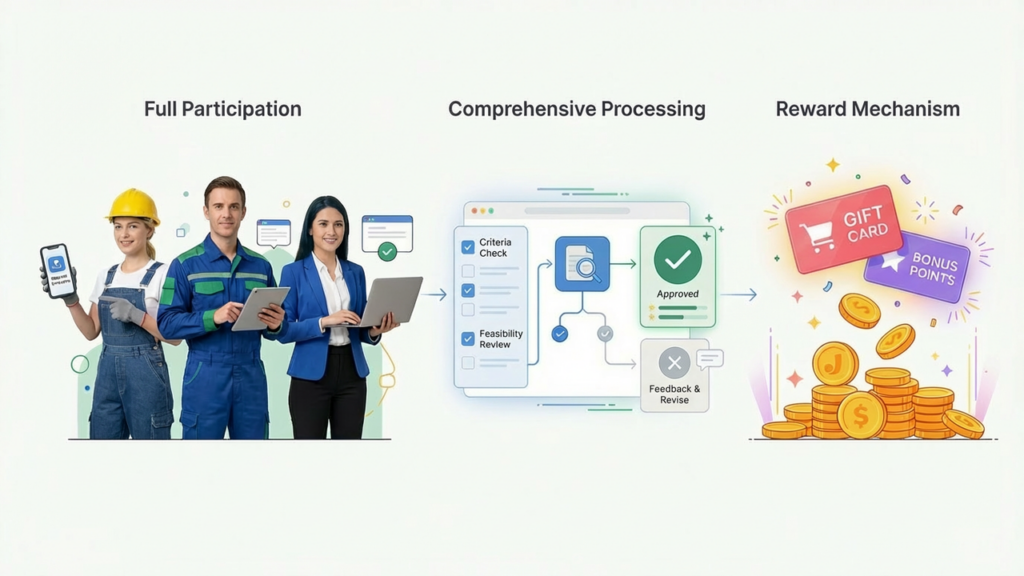

Employee Improvement Proposals

- Full Participation – Enable all employees to submit improvement proposals conveniently through a mobile platform.

- Comprehensive Processing – Once a proposal is submitted, relevant personnel evaluate its validity. Approved proposals proceed to the implementation stage, and the initiator is notified of the progress.

- Reward Mechanism – After successful implementation, appropriate rewards are provided to the proposer, ensuring active participation from all employees.

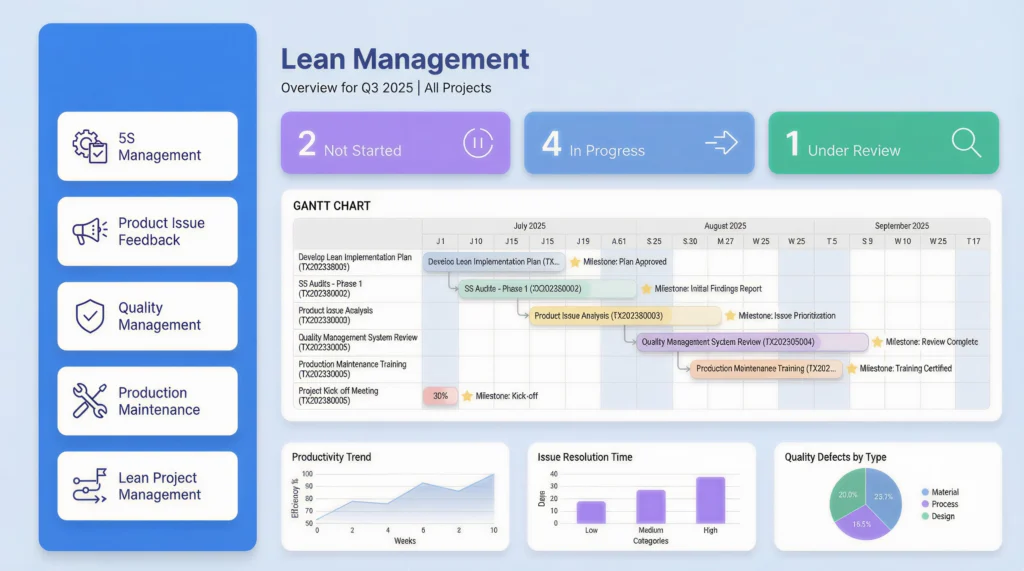

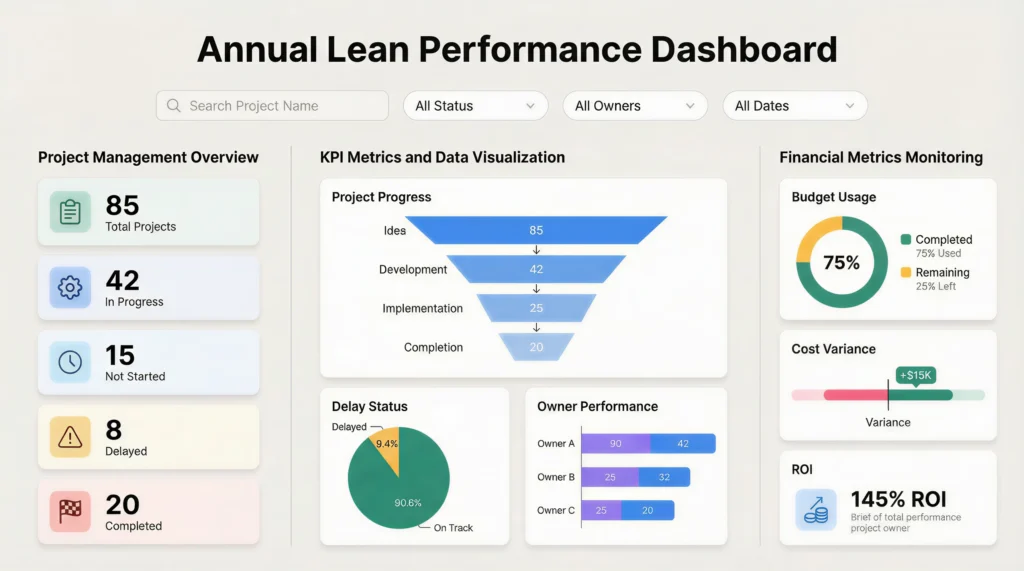

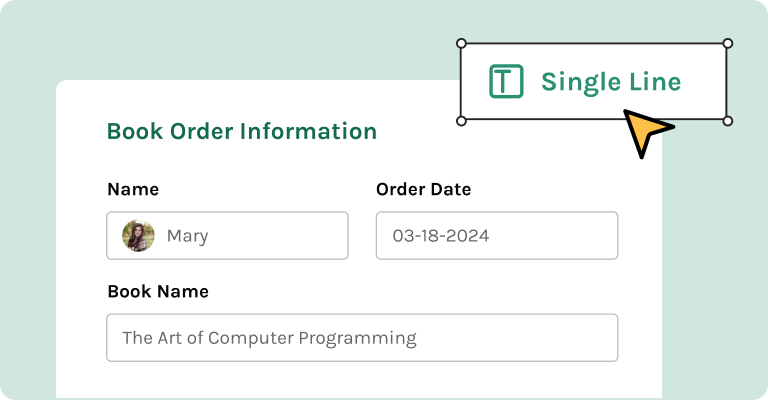

Lean Improvement Projects

- Annual Lean Performance Management Model – Help companies manage and achieve lean objectives through an annual performance management framework.

- Lean Project Management – Streamline task management, schedule tracking, and quantitative financial calculations for lean improvement projects.

- KPI Management and Data Visualization – Manage key performance indicators (KPIs) and leverage BI tools for data visualization and analysis.

Why Jodoo

Deploy instantly with ready-made templates

Leverage proven lean practices to quickly implement and customize templates, accelerating your lean transformation.

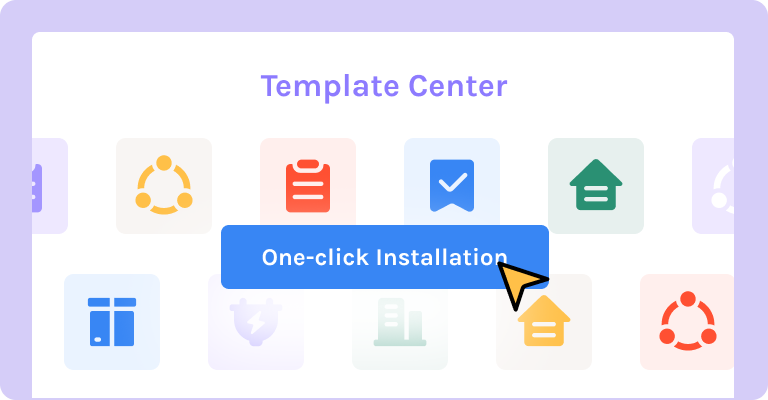

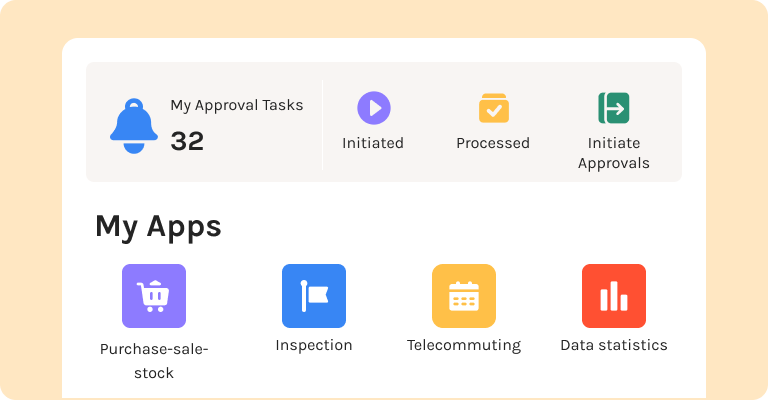

Build custom apps with intuitive drag-and-drop builders

Easily create forms, automations, and dashboards without coding. Adapt to various lean improvement scenarios and factory-specific needs.

Manage work the way you prefer across any device

Switch between Gantt, Kanban, and grid views to match your workflow. Access and update your data on desktop, tablet, or mobile in 12 + languages your crews actually speak.

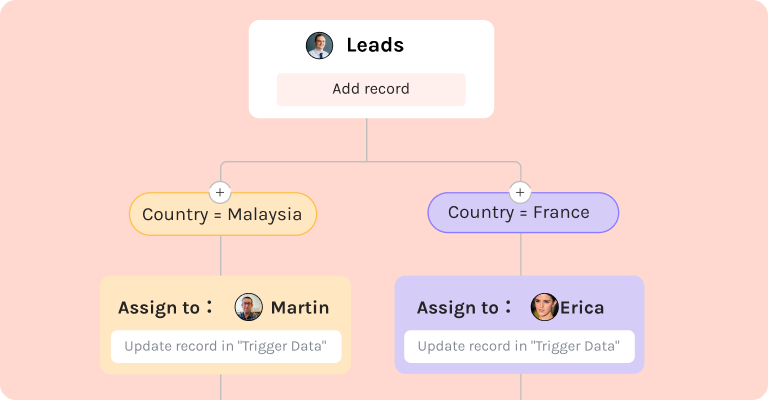

Automate routine processes and approvals

Set up automation rules for approvals, notifications, and reminders. Streamline repetitive processes so your team can focus on what matters most.

Automate your contract and site approvals

Link every workflow—HR, finance, operations, CRM—on a single platform. Ensure real-time insights with synchronized, easily accessible data.

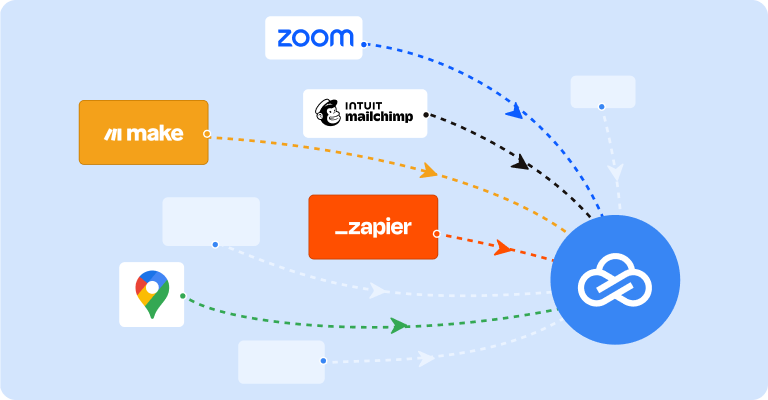

Integrate and scale as your business grows

Connect easily with third-party tools and systems. Expand to support more users, apps, and data without limits on capacity or performance.

Your security is our top priority

Ready to Take Control of your Lean Management? – Book a Demo Now!

FAQs

Jodoo is a SaaS-based no-code application builder that helps you quickly create the applications you need (such as inventory and order management), and provides real-time dashboards and fully customizable workflows to optimize operations.

Lean management comes from lean production and is a way to improve production and operations. By systematically eliminating waste in processes, you can reduce the people, space and capital required, shorten lead times, and improve quality and quality-related costs.

Define value from the customer’s perspective; use value stream mapping to identify and eliminate waste; keep materials and information flowing smoothly; adopt pull production when conditions allow; and use PDCA cycles and broad participation to drive continuous improvement.

It is usually divided into three phases:

1. Foundation (0–3 months): Shop-floor 5S, visual management and value stream mapping to identify major wastes.

2. Process control (3–9 months): Pull production, Kanban, standard work, multi-skilled operators and TPM.

3. Performance evaluation and continuous improvement (9–12 months): Build KPI dashboards and lean cost accounting, and turn improvement proposals into a regular practice.

It’s suitable for both. You can start with a single line or warehouse as a pilot, and our no-code templates let you launch quickly and expand later.

No. Lean or business teams can configure the core workflows themselves. IT is usually only needed when deep integration with ERP/MES is required.

In the short term (a few weeks) you can see quick improvements such as boards, 5S and basic Andon. Broader or site-level results usually take a few months, depending on the deployment scope.

Yes. Jodoo supports Excel import, webhooks and APIs so that data can be interconnected between systems.

Convert pilot results into standard work: use templates, clarify task ownership, set reminders and track basic KPIs, so that improvements become part of daily routines.