100+ apps

Custom apps in one workspace

10 districts

Convenient regional system collaboration

3m saved

Enables rapid cross-factory replication

The IDEA platform’s name is derived from four keywords: Innovation, Digitalization, Elevation, and Activation. With Jodoo’s no-code platform, we achieved what would have taken months in just weeks. The flexibility and scalability of the platform have been game-changing for our digital transformation journey.

—— Head of Industrial Digitalization for BASF’s Asia, Dr. Wang

The BASF Group has more than 160 wholly-owned subsidiaries or joint ventures in 41 countries in Europe, Asia, North, and South America, and employs approximately 112,000 people worldwide. BASF offers customers a wide range of high-performance products, including chemicals, plastics, specialty products, crop protection products, and crude oil and natural gas. In August 2020, the Fortune Global 500 list was released, and BASF ranked 143rd.

As the world’s leading chemical company, BASF faced challenges in scaling digital solutions across its global operations. With Jodoo’s no-code platform, BASF saved 3+ months in deployment time, streamlined collaboration across 10+ regions, and launched 100+ custom apps to support its Industry 4.0 goals.

The challenges

Slow iteration speed

In the highly regulated chemical industry, BASF needed to adapt quickly to ever-changing compliance requirements. Traditional development methods often require months to implement even minor updates, delaying critical operations and increasing costs.

Inefficient system replication

With over 10 production sites in the Asia-Pacific region, replicating systems across locations was time-intensive and resource-draining. Each deployment required extensive manual configuration, leading to delays and inconsistencies.

Lack of customization in digitalization pathways

BASF aims to implement Industry 4.0 in phases, starting with process digitalization (Industry 2.0), followed by system coordination (Industry 3.0), and finally achieving smart manufacturing (Industry 4.0). The immediate focus is to establish a strong foundation for digitalization to support future system integration.

The solution

To overcome these challenges, BASF leveraged Jodoo’s no-code platform to create the IDEA application platform. This privatized cloud-based solution enabled BASF to rapidly develop and deploy applications without requiring traditional coding expertise. By late 2022, the platform had launched over 100 applications, including contractor management and change management systems, significantly improving operational efficiency and scalability. This serves as a benchmark for BASF’s Asia Pacific region’s single business units and a model for accumulating best practices.

Contractor management application: enhancing platform synergy

The contractor management application streamlines operations in chemical parks by ensuring safety and efficiency for large-scale contractor activities.

- Pre-Entry Registration: Contractors register via the IDEA platform, providing details for approval before uploading worker information and qualifications.

- Safety Training: Workers complete standardized safety training, including video sessions and exams, before commencing work.

- Performance Monitoring: The system tracks workers’ performance, recording rewards and penalties.

A “One Worker, One Profile” system consolidates certifications and violation records. Workers with three violations are blacklisted, with automatic suspension of qualifications. The application eliminates data silos, enabling seamless information flow and reducing repetitive offline tasks. It allows for efficient online management of large-scale worker data with full traceability.

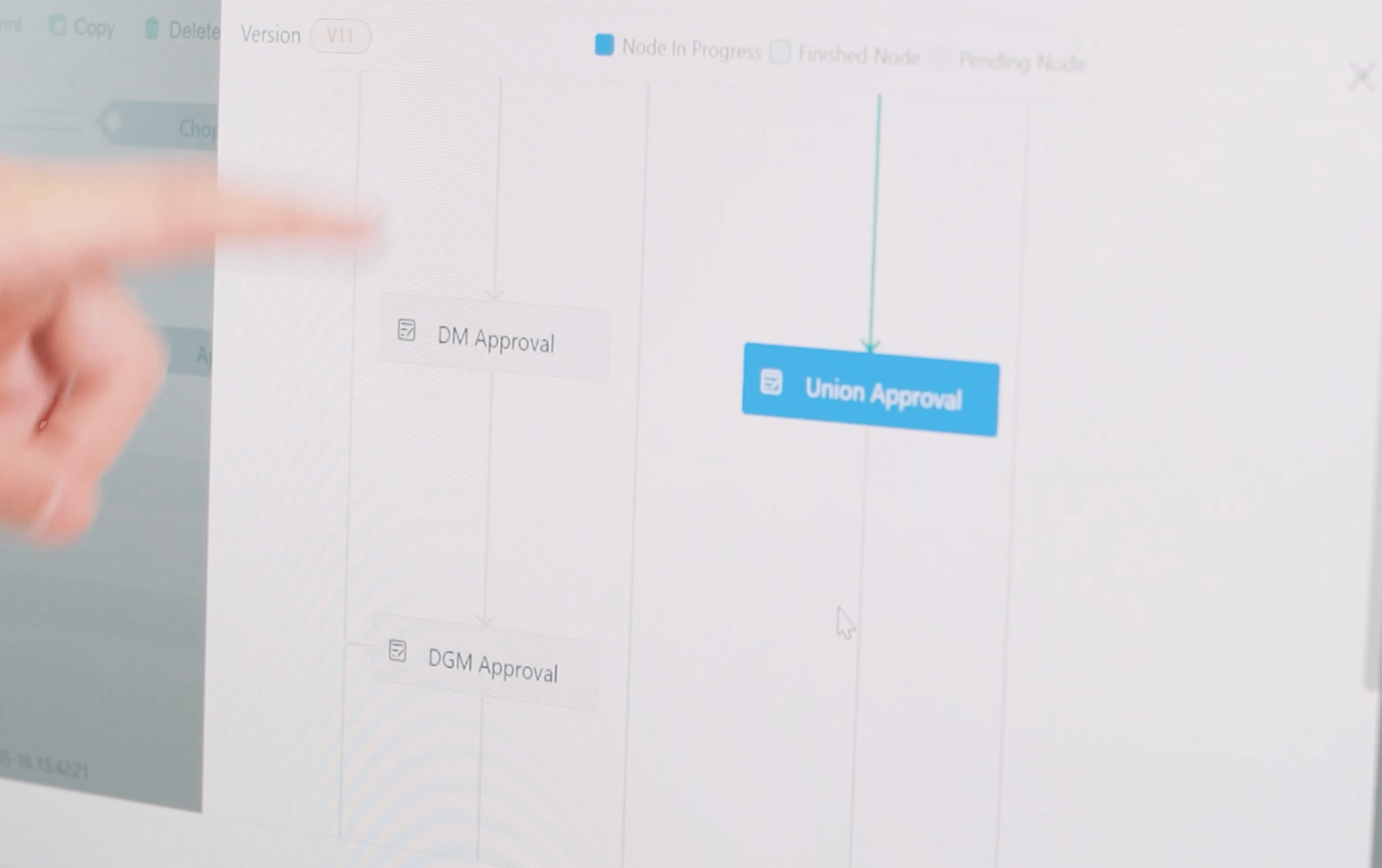

Change management application: efficient replication of No-Code complex solutions

Change management is a critical risk control process in the chemical industry, requiring multi-department evaluation, approval, and record-keeping. BASF partnered with the Jodoo team to develop a no-code change management application:

- Visualized Workflow and Audit Support: Change approval records can be exported to ensure compliance, reduce audit risks, and enhance production safety.

- Cross-Border Replication and Optimization: After successful implementation in one district, the application was replicated for use in Korea. Factories can customize permissions, enabling real-time adjustments during trial runs.

This solution demonstrated the feasibility of no-code development for complex applications and established an efficient path for cross-country deployment. The “replicate + permission adjustment + optimization” approach accelerates implementation and reduces costs compared to traditional methods.

Digital transformation: amplifying impact with minimal effort

BASF has launched various applications on the IDEA platform, including contractor and change management systems, a hazardous chemicals prevention system, and a task system with over 20 templates like Meeting Minutes and Accident Reports. These tools reduce reliance on paper-based processes, promoting greener, more efficient operations.

BASF emphasizes “leverage” in digitalization, aiming to amplify management efficiency. Through Jodoo’s no-code development, BASF’s digital transformation team quickly builds complex applications, enabling collaboration across independent systems. This approach addresses key digitalization challenges in the chemical industry and facilitates cross-factory implementation, empowering efficient operations.

In the future, BASF aims to use the platform to fill gaps in information management, enhance connectivity between different platforms, and achieve broader synergy. Ultimately, this will provide a strong foundation for further exploration of Industry 4.0.

Ready to accelerate your digital transformation like BASF? Discover how Jodoo can empower your business with no-code innovation. Request a Demo Today.